No products in the cart.

Return To ShopSectioning

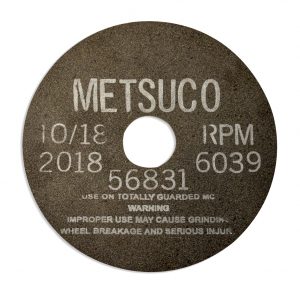

Any time a specimen needs to be separated from its parent piece for testing purposes, it is very important that the specimen has minimal wear, no thermal damage or burns, and is as smooth as possible. Otherwise inspection, especially at the microscopic level, will not be representative of the parent piece. This is accomplished by using abrasive cut-off wheels in combination with a lubricating cooling fluid to remove debris and avoid damaging friction heat.

METSUCO has a full lineup of sectioning equipment, aluminum oxide cut-off wheels, and silicon carbide cut-off wheels in various sizes and for use with various hardnesses. We also sell diamond cut-off or sectioning blades and cubic boron nitride (CBN) blades for use on very hard metals, carbides, and ceramics. More recently we started selling band saw blades for cutting larger pieces of metal that can then be cut further by cut-off wheels for sample preparation or just for general production purposes. Our band saw blades come in bi-metal or carbide tipped if needed and in varying teeth per inch (TPI) or lengths depending on need.

METSUCO has been in business for over 30 years, sourcing quality supplies at economic prices. We offer 24/7 ordering, quick shipping, and a dedicated support staff. Don’t see the right product? Contact us, we can help with your quality testing needs!

Product Categories

Aluminum Oxide Abrasive Cut-Off Wheels – 10″

$160.00 If you would like to request a sample, click the button below, then choose which specific product sample to add to your cart. 10″ Diameter x 1 1/4″ Arbor Priced per box

Aluminum Oxide Abrasive Cut-Off Wheels – 12″

$172.51 – $200.00 If you would like to request a sample, click the button below, then choose which specific product sample to add to your cart. 12″ Diameter x 1 1/4″ Arbor Priced per box

Aluminum Oxide Abrasive Cut-off Wheels – 9″

$135.00 – $155.00 9″ Diameter x 1 1/4″ Arbor Priced per box.

Bi-Metal Band Saw Blade

$60.93 14′ 6″ x 1″ x 4-6 Bi – Metal Siclone band saw blade Brand : Simonds *Available in other sizes upon request

Bitec Plus Band Saw Blade

$46.25 13′ X 3″ X 1″ 3-4 Bitec band saw blade Brand : Simonds *Available in other sizes upon request

CF S-Line Abrasive Cutters

The CF line of metallographic abrasive cutters, S Series, is our most powerful group of abrasive cutters. These abrasive cutters are able to use cutoff wheels from 12″ (305mm) to large blades of 20″ (508mm). the S-Series abrasive cutters are capable of cutting pieces of up to 6″ (150mm) in diameter, with a cutting depth of 18″ (450mm), and a cutting height of 250mm. A strong hydraulic system drives both the stainless steel bed and cutoff wheel movement. (Please see Product Sheets to download a spec sheet). Features include: Meter display of motor load Easy store magnetic spray gun for cleaning Auto...

CF-250B 12″ Abrasive Cutter

The CF-250B Precision Cutter allows precise, laser guided cutting to achieve absolute parallelism and lack of deformation. Parameters are easily set for all type of materials. Includes vises and recirculating system.

CK Line Abrasive Cutters

CK Abrasive Cutters for the metallographic lab are robust, easy to use and competitively priced. With strong motors ranging from 3hp to 10hp, the line is versatile and able to cut anything from small delicate parts, to large, hard to cut materials.

CL-50 High Speed Sectioning Saw

The CL-50 High Speed Precision Saw is an excellent addition to any materials lab where hard to cut or brittle materials must be cut allowing no deformation and needing parallelism. All parameters are easily set using touch screen controls.

CL-70C – High-Performance Table-Top Lab Saw for Metallography | PSI Metallography

Experience the power and precision of the CL-70C Table-Top Lab Saw. PSI Metallography offers this cutting-edge tool designed specifically for metallography applications. Enhance your laboratory workflow and achieve accurate results with ease.

CL40 Low Speed Sectioning Saw

PRECISO Model CL-40, Low-Speed Sectioning Saw, uses diamond and wafering blade cutoff wheels 3″-5″. This low-speed sectioning saw has loading pressure from 0-400gm, 40W motor, rotational speed 0-400 rpm, comes with a 4″ high concentration diamond wafering blade, and is designed for operation on AC 110V-220V, 1ph. Download Datasheet CL40 Low Speed Abrasive Cutter Specifications MODEL CL40 MOTOR POWER 40W CUTTING BLADE 3″-5″ MAX DIAMETER CUT 40mm/1.5″ FEEDING METHOD Gravity fed, wheel stops when cut is finished ROTATIONAL SPEED 0-400 RPM NOISE LEVEL 55-62dB COOLANT TANK 400mL MACHINE WEIGHT 19kg/50lb POWER 110V/220V-1ph

CLM-50 Precision Sectioning Saw

The CLM-50 is a compact, table-top precision cutter for the metallographic lab. Uses both abrasive cutoff wheels and diamond blades. Adjustable speed and easily set feed rate.

Diamond Cut-Off Wheels – High Concentration Metal Bond

$180.00 – $324.00 If you would like to request a sample, click the button below, then choose which specific product sample to add to your cart. Continuous rim diamond cutoff (wafering) blades are recommended for aggresive general laboratory sectioning of ductile materials, most metals, polymers, pc boards, thermal spray coatings and titanium. Priced per each.

Diamond Precision Sectioning Blade – High Concentration Metal Bond

$180.00 – $324.00 If you would like to request a sample, click the button below, then choose which specific product sample to add to your cart. Continuous rim diamond cutoff (wafering) blades are recommended for aggresive general laboratory sectioning of ductile materials, most metals, polymers, pc boards, thermal spray coatings and titanium. Priced per each.

Lubricant Cutting Fluid

$25.00 – $95.00 If you would like to request a sample, click the button below, then choose which specific product sample to add to your cart.

Negative Rake Carbide Band Saw Blade

$260.00 Simonds 1″ X 042 X 2.5-3.5 Negative Rake Carbide band saw blade Benefits: Negative tooth tip rake angle provides greater tip strength able to penetrate high hard materials and surface coatings Plastic Capping prevents tooth damage during shipping and handling Materials: Heavy chromed shafts Induction hardened shafts Linear bearing shafts Applications: For cutting hardened materials up to 65 Rc on power feed saws when machinability is a challenge. *Available in other sizes upon request

Siclone Band Saw Blade

$54.00 Simonds 14′ 6″ x 1″ x 4-6 Siclone band saw blade Benefits: Designed for constant feed and pressure machines – user friendly blade Unique tooth geometry prolongs blade life and minimizes work-hardening 8% cobalt high speed steel teeth laser welded to premium backing steel improves performance Oversize blade width increases beam strength Materials: Iconel D2 Stainless Steel Monel & other exotic alloys Applications: Steel service centers Production cutting *Available in other sizes upon request

Silicon Carbide Abrasive Cut-Off Wheels – 12″

$184.00 If you would like to request a sample, click the button below, then choose which specific product sample to add to your cart. 12″ Diameter x 1 1/4″ Arbor Priced per box

Silicon Carbide Abrasive Cut-Off Wheels – 9″

$145.00 If you would like to request a sample, click the button below, then choose which specific product sample to add to your cart. 9″ Diameter x 1 1/4″ Arbor Priced per box

Triple Chip Band Saw Blade

$218.00 Simonds 14’ 6” x 1” x 3 Triple Chip band saw blade Benefits: High Carbide tipped teeth increase wear resistance cutting high temperature alloys Triple Chip geometry provides a smoother surface finish Positive rake angle allows faster penetration for high production cutting Plastic capping protects teeth against damage in transit and handling Materials: High nickel Alloys Titanium Aluminum Bronze Inconel and other exotic materials Applications: Production cutting operations Steel service centers Foundries Aerospace *Available in other sizes upon request