Sample Preparation – Sectioning and Mounting explained

Sample preparation for tests such as the hardness test are critical when it comes to quality control, production, and engineering. Last month we went over the grinding and polishing of samples. Now we are going to explain the sectioning and mounting process of sample preparation.

Sample Preparation – Sectioning and Mounting Explained.

Sectioning

The sectioning part of the sample preparation is where the sample is cut or “sectioned” off from the main material source. One of the most important aspects of sectioning is to not alter the microstructure or damage fracture features when cutting a specimen. If an abrasive saw is used, it is important to keep the sample cool with lubricant or coolant. The damage to the specimen during sectioning depends on the material being sectioned, the nature of the cutting device, the cutting speed, feed rate, and the amount and type of coolant used.

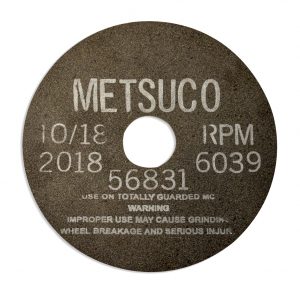

Abrasive cutting is the most widely used method of sectioning. This technique uses low-speed cut-off wheels in cases where the heat created by standard abrasive cutters must be avoided. A cut-off wheel consists of abrasive grains (such as Aluminum Oxide or Silicon Carbide), bonded together with rubber or other materials in the form of a thin wheel. Rubber bonded wheels are most extensively used for wet operation and resin bonds for dry cutting. In some cases, diamond and grinding cut-off saws are used to section materials while still retaining a reasonably smooth cut surface, necessary for proper grinding and polishing.

Another sectioning method, though not as commonly used, is using a band saw. In some cases, it might be best to use a hand-held band saw for rough sectioning. Hand-held band saws generally do not generate enough frictional heat to alter the microstructure.

Mounting

After the specimen is sectioned to a convenient size, it is mounted in a plastic or epoxy material to facilitate handling. Small test samples typically require mounting before proceeding to the grinding and polishing steps of metallographic sample preparation. There are two main reasons for mounting metallurgical samples. The first is for convenience in handling samples of difficult shapes or sizes during the subsequent steps of metallographic preparation and examination. The second is mounting protects fragile or coated materials during preparation and to obtain perfect edge retention.

Mounting can be completed “hot” with a mounting press and different hot mounting compounds that combine heat and pressure to cure the mounting mold. This is also known as compression mounting and is the most common mounting method. Yet not all samples can tolerate heat. In these cases, mounting can be done “cold” with a curing resin. The curing resin is usually epoxy or acrylic-based. The cold mounting is achieved by taking the epoxy or acrylic and pouring it over a sample that is positioned face down in a cold-mounting ring.

Metallurgical Supply Company (METSUCO) has been a leader in affordable sectioning and mounting supplies. Some of the industries we serve are oil and gas, aerospace, automotive, heavy manufacturing, universities, and quality testing labs. You can order supplies and consumables from https://metsuco.com/shop/ or call 713-827-0700. You can also email sales@metsuco.com with inquiries.