In the precise world of metrology, accuracy is the foundation of progress. Whether you are working in manufacturing, pharmaceuticals, aerospace, or research, reliable measurement tools are essential to ensure quality, compliance, and innovation. At METSUCO, we understand the importance of having the right tools in your lab. Here’s a look at the essential metrology instruments every laboratory should have to excel in accuracy and efficiency. Calipers and Micrometers Why They Matter: These tools are indispensable for measuring small dimensions with incredible precision. From inspecting mechanical parts to ensuring consistency in production, calipers (digital, vernier, or dial) and micrometers are... Continue reading

713-827-0700

sales@metsuco.com

At METSUCO, our mission has always been to provide top-tier solutions that empower businesses and individuals to achieve their goals. Over the years, we’ve been privileged to work with incredible customers who’ve shared their success stories with us. These testimonials not only validate the quality of our products and services but also inspire us to continue innovating and improving. Here are a few remarkable success stories from our customers who have experienced tangible results with METSUCO. Streamlining Operations for a Growing Enterprise “Before using METSUCO’s solutions, managing our expanding operations was chaotic. We lacked the tools to coordinate effectively across... Continue reading

As the world advances into a new era of digital transformation, the metallurgy industry is witnessing unprecedented changes driven by technologies like Artificial Intelligence (AI) and the Internet of Things (IoT). These technologies are reshaping how metals are produced, tested, and managed, offering solutions that boost efficiency, optimize processes, and enhance quality. At METSUCO, we are closely following this transformation, recognizing the power of AI and IoT to revolutionize metallurgy and unlock new possibilities in metals research, production, and performance analysis. The Power of AI in Metallurgy Artificial Intelligence is redefining metallurgy by providing intelligent insights into complex processes. Traditionally,... Continue reading

In an era where technological advances are driving the industrial landscape, metallurgy stands as a crucial foundation supporting everything from aerospace to renewable energy. Yet, inspiring the next generation of metallurgists to carry this field forward requires more than a traditional classroom approach—it demands hands-on experience, modern labs, and real-world applications. At METSUCO, we’re committed to nurturing young talent by bridging the gap between classroom theory and laboratory practice, fostering an environment where students can explore and innovate. The Role of Metallurgy in Today’s World Metallurgy is the science and engineering of metals, and it’s the backbone of industries that... Continue reading

To ensure the safe and responsible disposal of metallurgical supplies, it’s important to follow a systematic approach. Below are some key steps to consider: 1. Identify and Classify Waste Materials Before disposing of any materials, it’s essential to identify and classify the type of waste you have. Common categories of metallurgical waste include: Chemical Waste: Acids, solvents, and other chemical reagents. Solid Waste: Contaminated metals, used abrasives, and other solid residues. Hazardous Waste: Materials that pose a risk to health or the environment, such as toxic or flammable substances. Understanding the nature of each waste type will help you determine... Continue reading

In the field of research and development, utmost importance is placed on accuracy, precision, and reliability. Whether you’re working in a laboratory, a manufacturing facility, or an industrial setting, the quality of your research outcomes depends heavily on the performance of your equipment. At METSUCO, we understand the importance of keeping your tools and machines in top condition. In this blog post, we’ll explore how regular equipment maintenance can significantly impact research outcomes and why it’s essential for maintaining the integrity and success of your projects. The Importance of Equipment Maintenance in Research Research equipment serves as the cornerstone of... Continue reading

When you think of the energy industry—whether it’s power plants, renewable energy farms, or even pipelines—you might picture large structures made of metal, steel, and other robust materials. But what ensures these materials are strong and reliable enough to handle extreme environments and demanding applications? That’s where hardness testing comes in. In this article, we’ll walk you through why, using hardness testers, hardness testing is so crucial to energy companies and how it helps ensure safety, efficiency, and cost savings across the board. So, whether you’re a technician in the field or just curious about how power gets from the... Continue reading

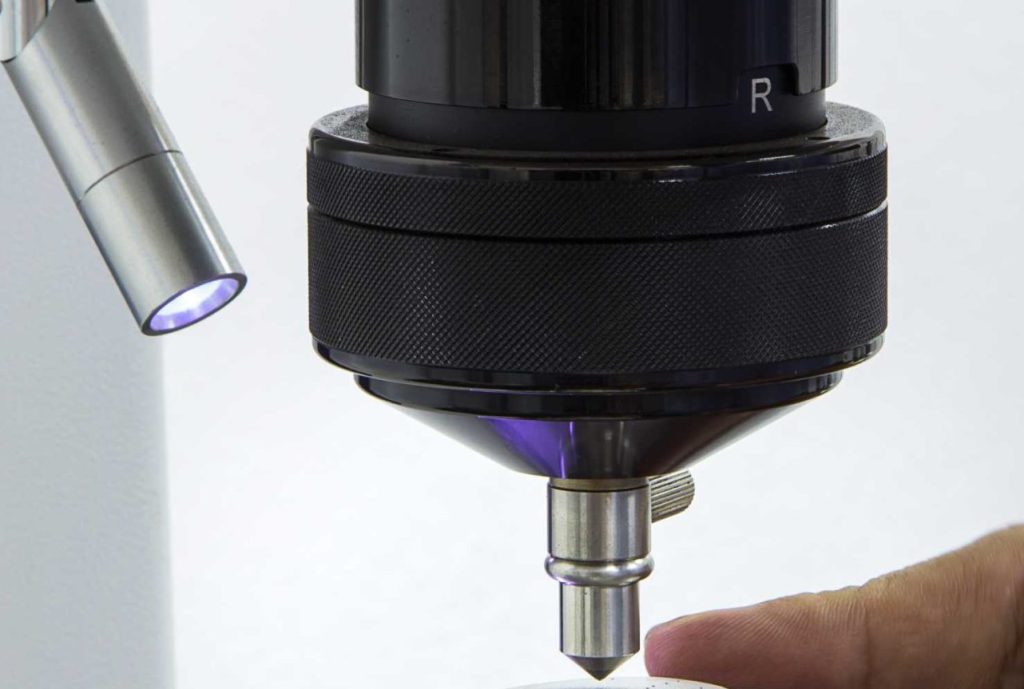

Selecting the appropriate hardness test for your materials is crucial for ensuring product reliability and performance if you are a structural engineer or in product and design, whether you are in oil and gas, aerospace, automotive, or another industrial sector. At METSUCO, we specialize in providing precision hardness testing equipment that caters to diverse industrial needs. Specifically for this article, we are going to focus on the Knoop hardness test. We are going to be highlighting when it is the most suitable choice for materials testing, especially in comparison to other popular methods like the Vickers and Rockwell tests. Overview... Continue reading

Knife collectors can put their knives through some crazy situations. That means knife manufacturers need to make durable knives that can stand these real work use cases. One of the most reliable methods for assessing the durability and functionality of knives is the Rockwell Hardness Test. You may have heard about the Rockwell hardness of a knife on knife shows and collector exhibits. However, there are more hardness tests and scales than just Rockwell. So why is this one chosen to test knives? We are going to explain why this particular test is the preferred choice among knife manufacturers and... Continue reading

In a vast array of industries, engineers, production teams, and manufacturers rely on various hardness testing methods to assess the mechanical properties of materials accurately. Among these methods, the Vickers and Knoop hardness tests are widely used for their versatility and precision. While it is true we have covered Vickers testing extensively, often the two get confused for one another to those who are not in the trenches day to day. That is why we'll explore the differences between these two tests, their respective advantages, and when each test is best suited for specific applications. Understanding Vickers Hardness Testing The... Continue reading

Showing 31–40 of 87 posts