Benefits of a Digital Hardness Tester

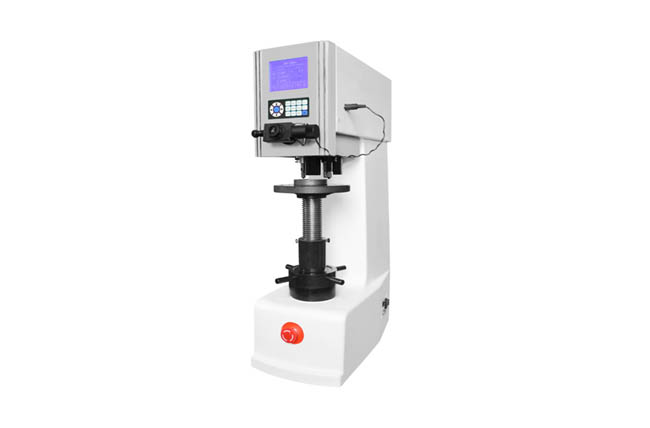

A Digital Hardness Tester is a measuring instrument used to determine the hardness of a given material. It is an essential tool in industries where metals and alloys are produced or used. This includes a variety of industries including auto manufacturing, aerospace, oil and gas, and many others. Testing the hardness of metal including steel or composite alloys is essential to the integrity of the product being manufactured or the structure that is being engineered or constructed. Hardness testing uses hardness testers to detect flaws, delamination, and weak spots before they become costly and an embarrassment to the company. In the world of hardness testing, there are traditional analog hardness testers and there are digital hardness testers. A digital hardness tester provides numerous benefits compared to traditional hardness testers, which makes it an indispensable tool in many industries. That is why we are going to discuss the benefits of a digital hardness tester, and why you or your company might want to purchase a digital tester over an analog hardness tester.

Why Do Analog Hardness Testers Still Exist?

Let’s first talk about the elephant in the room. With everything now seemingly attached to an app or software, why is there ever a debate about whether or not to get a digital hardness tester over an analog one? Why do analog hardness testers still exist with everything nowadays being digital? The answer is there are engineers in labs and in product development or manufacturing that have been hardness testing for years. Some for 25-plus years which means well before digital hardness testers came out. Due to this, they are used to using the analog version and may feel like they just want to stick with that. The second reason is that analog hardness testers are cheaper than their digital counterparts in terms of upfront cost. If your department is on a tight budget, they may opt for an analog version instead.

Benefits of a Digital Hardness Tester.

However, when you weigh the benefits of digital hardness tester over buying an analog version, it usually just makes good sense to go digital. Here are a few reasons.

Accurate and Precise Measurements.

One of the primary benefits of a digital hardness tester is its accuracy and precision. No matter how accurate a person thinks they are in measuring and writing down data, there is always a chance for human error. In most cases, the purpose of doing the hardness test is too important to leave room for error. With the use of advanced sensors and software digital hardness testers measure the hardness of material accurately with little to no room for error. The digital display also allows for precise readings, which are essential for quality control and ensuring that products meet industry standards.

User-Friendly Interface.

To stay on the point of getting accurate readings, you need to be able to understand the data that is coming from the hardness tester, and easily control the tester to dial in the exact tests you need. Digital hardness testers are designed with a user-friendly interface, making them easy to use. The digital display provides clear and concise readings, and the tester’s controls are straightforward and intuitive. This ease of use ensures that operators can quickly learn how to use the tester, reducing the chances of errors and produces more accurate readings. This in turn produces test results engineers and manufacturers can trust.

Mounted Camera

With digital hardness testers, you also have the ability to have a camera mounted in the tester. This allows the ability to take images of subject material, before and after the test. The camera helps create the precise measurements and calculations needed. Many come with an automatic focus adjustment with precise positioning at a specified magnification. This reduces reading time and increases reading accuracy.

Data Storage and Analysis

Digital hardness testers come equipped with data storage capabilities that allow operators to store and analyze test results. The ability to store and analyze data is essential for quality control and ensuring that products meet industry standards. Data analysis also helps identify patterns and trends, which can help improve the production process and reduce costs. If needed, you can get printed readouts to be able to be documented in an excel-like format. This means you do not have to have someone there recording the readout, as the machine does that for you. This also cuts down the chance for human error.

Automating Test procedures and results.

“An automatic hardness system typically consists of a fully controllable tester, including an auto-rotating or revolving turret and actuation in the Z axis either from the head/indenter housing or from a spindle-driven system for both applying the indent at a predetermined force as well as for focusing the specimen. Add to this a desktop or laptop computer with dedicated hardness software installed, an automatic XY traversing motorized stage and a USB video camera, and the result is a powerful, fully automatic hardness testing system.” https://www.qualitymag.com/articles/87616-hardness-testing-gets-automated

Cost Effective in the Long Term.

While digital hardness testers may have a higher upfront cost compared to traditional hardness testers, they offer long-term cost savings. The accuracy and precision of digital hardness testers reduce the need for additional testing and reduce waste, saving costs in the long run. The ability to measure the hardness of various materials using a single instrument also reduces the need for multiple instruments, further reducing costs.

It may be tempting for a company on a tight budget to go for an analog hardness tester. However, investing in a digital hardness tester, industries can improve quality control, increase productivity, and reduce costs, leading to increased profitability and success. The ability to get more accurate measurements, better readout and analyzation of those measurements and reduction of human errors all lead to better construction and products out on the field with less chance of costly failures. In the long run, it just makes sense to go with a digital hardness tester.

METSUCO has been a leading supplier of hardness testing machines and blocks for over 30 years. We serve not only industries such as oil and gas, aerospace, automotive, and heavy manufacturing, but also universities and quality testing labs. Call 713-827-0700 or email sales@metsuco.com with inquiries.